Imagine Patterns: Making the MK3 Bib Short

Words: Pete Harrington

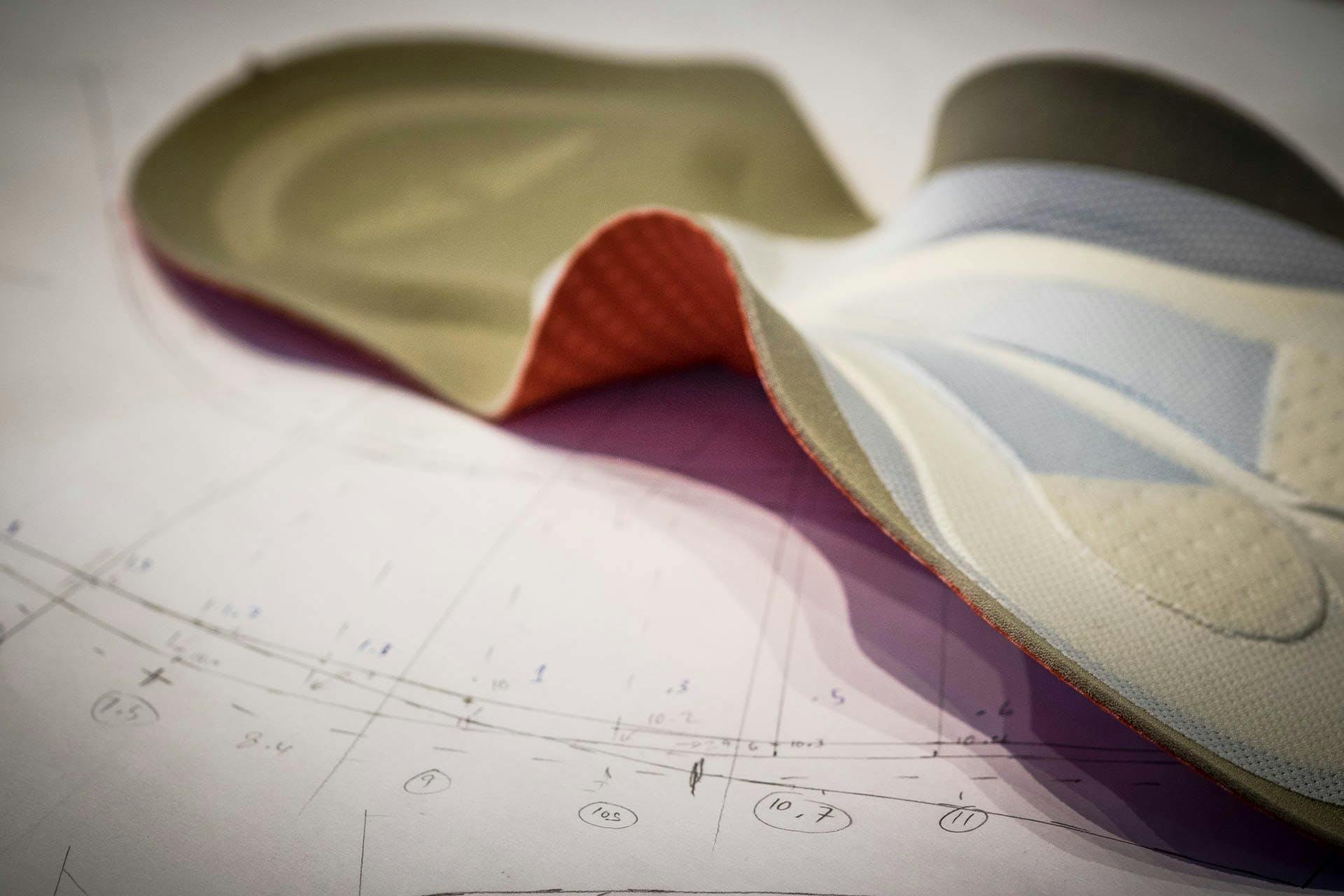

With the release of the MK3, the third version of our refined, long-distance road cycling bib short, we got to thinking about design, quality, and the process of continual improvement. In our world, everything is an iteration – a tweak or change towards something better. Not that we don’t have pause points; it’s just that when a product is released, we keep developing. Whether it’s new fabrics, new thoughts, rider feedback or changing tastes, there’s always a path towards a future, imagined version. Which, if you’re in the business of making considered products, is just the nature of things.

Back in late January we took the opportunity to sit down with 7mesh VP Product, Ian Martin to talk MK3, fit, fabrics, and the process of product evolution.

After so many months in development, how does it feel to have a product reach the light of day?

Pretty amazing! There are moments when you doubt your idea will ever see fruition. Creating products is such a long game, and you need to have good reserves of patience, that’s for sure.

Once a product ships, at what point do you feel strongly enough that a new iteration is necessary, or even possible?

It’s not so much one point. A lot of times you know the exact changes that you would like to incorporate into the next version by the time you finish the latest version, but know they will take a lot more time to develop and dial. Take the MK2: a small, but important iteration of the MK1. It’s got the same fabric as the MK1, but a load of little improvements that come together to make something significantly better, like the grippers and a longer leg length. That same process led us to the MK3, but on a whole new level – the MK3 is a significantly improved short over the previous versions.

What can riders expect from the new short?

Well, when you’re iterating the same product, you’ll always end up with a short that keeps the feeling of the previous model, so riders who love the MK line are going to feel right at home. But pulling them on, and wearing them is going to be next level.

That’s big talk.

Ha, I know! But from the get-go, we decided, “Let’s make MK be what it needs to be,” which is a kind of everything road cycling bib short built for fondos, Sunday spins, chain gangs – you name it. And to get it there, we needed to up the durability of the fabric. Which is why, compared to the MK2, it won’t feel as silky smooth on the first touch. But, it’s going to feel more compressive – let’s say supportive – more breathable, and, way more durable over the big miles.

Does that mean you messed with the fit?

Not a whole lot. The fit is pretty much as the MK2 – that was one thing nobody wanted us to change. The big change comes at the grippers, where instead of having the extra piece of material stitched to the hem to house the gripper, with the new fabric, we could print on the inside of the main body fabric. In one fell swoop, the hem fit and feel got so much better. Do you know the sausage casing effect? That’s when the gripper overly compresses the leg in comparison to the body fabric. Well, by printing the gripper on the inside of the main material, we could feather out the hem. And the feeling is fantastic. Honestly, you’ve got to try it.

The hem also looks a lot neater.

Yep, that’s our Clean Finish ethic at work. We tailored the hem with a raw cut edge, which further smooths out the bib. On the bike, our goal was that you wouldn’t feel the bib in any one place. You’re wearing it, so of course, you know it’s on, but you shouldn’t feel where the hem ends.

You mentioned a compression effect – does that affect sizing?

I wouldn’t think so. Whatever size you are in the MK2, the MK3 will fit similarly, albeit with a more compressive ‘power’ fit. But if anyone is in doubt, my advice is always to go down a size, rather than up, just because a closer fit makes the chamois more precise. Everything works better on the short when it’s worn closer to the skin.

Did rider feedback inform the more durable fabric of the MK3?

The biggest motivator for the change was overall bib durability for the long haul. But we also consulted with riders who wanted to see better resistance to velcro snags from seat bags. Velcro is never going to make nice with other materials, but the MK3’s new body fabric does better resist velcro. And, Brooks saddles! Honestly, we love the Cambium line here, but that atypical top surface does work against bib longevity. Thankfully, the new fabric should address that issue.

Summers these days seems to be getting hotter and longer. What that in mind, how does the MK3 handle the heat?

The new fabric will help there, too. While more durable, it’s also more sheer, so it should up the airflow considerably. But more importantly, we reimagined the chamois, reducing the front modesty panel by an inch, inch and a half to give a much freer feeling.

Is it a new model of chamois?

Yep, it’s a new Elastic Interface model, made to our specs with HDF (high-density foam) through the centre channel which helps with blood flow and vibration reduction. When you’re down on the drops pressing on the perineum area, that’s going to make everything seem so much smoother. But equally important is the new top sheet, which is a completely air permeable perforate layer of foam. Taken together, it’s a more comfortable and breathable bib, with a feeling of ‘less pad’ throughout.